Controlling and Testing

For ensuring the quality production required, continuous inspection and testing is necessary throughout the production process. In ELCOM, we work with the inter-operative optical inspection and the entire output control after any technologic operation of PCB assembling and soldering process. All this with the use of modern technologies.

Testing and Controlling systems:

- hardware component testing and programming

- computer automation testing

- SPI - Solder Paste Inspection

- AOI system - Automatic Optical Inspection

- ESD product testing (Electrostatic Discharge)

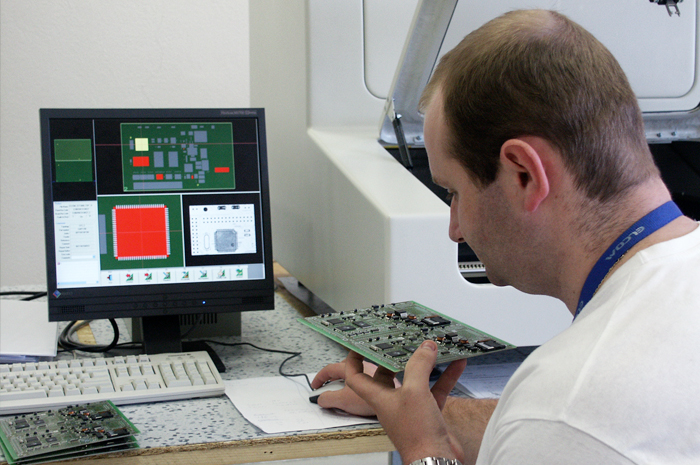

All electronic modules and PCBs are tested after soldering on a single-purpose tester, the Automatic Optical Inspection/AOI system Marantz 22 X DL for components positioning and soldering parameters, and an ICT tester Digitaltest MTS 180 for component electrical parameters and assembly checking. If it is necessary, we also use the functional testers which are built for concrete product type.

We also dispose of superior technologies for maintenance and service of damaged electronic boards, for BGA reballing and for repairing of micro BGA components. We perform debugging of DPS according to customer conditions. For this activity is necessary to supply the documentation for testing and draft of tested device connection.

|

|

|

| > PRODUCTION OF PLASTIC COMPONENTS | > MATERIAL PURCHASE | > CONTROLLING AND TESTING | >PACKING AND TRANSPORT |

|

|

Cash registers

Cash registers POS systems

POS systems External devices

External devices Accessories

Accessories Industrial computers & tablets

Industrial computers & tablets Signature solutions

Signature solutions Monitors

Monitors Accessories

Accessories

Adding product to shopping cart

Adding product to shopping cart